Welding is a proven method of securing infrastructure-related and fabricated metal joints, and is often the preferred method in a wide range of applications. However, welding it is not without drawbacks that can affect its suitability for a number of applications. As an alternative to welded joints, engineered fasteners can provide significant time and cost advantages, depending on specific project factors and design requirements.

When evaluating whether welding or fastening is best for a particular installation, a variety of factors must be considered. In the final analysis, the type of joint to be specified and fabricated depends on project factors as well as operational preferences.

Project factors that guide the selection of joint type include: the weldability of the materials to be fastened (including surface coatings that may be affected by heat), joint types, installation processes and logistics, inspection requirements, cost, labor availability, accessibility, environmental conditions, safety, and future maintenance/repair considerations. Any or all of these variables can be a potential factor in deciding whether to fasten or weld a joint.

This paper will discuss some primary considerations involved in choosing between welded joints or fastened joints, or some combination of both. By taking these factors into consideration, design engineers, project managers, fabrication supervisors, and construction management can make design and joining decisions that improve performance, increase safety and productivity, and control costs, while meeting and exceeding performance requirements over the lifecycle of the project.

The process of welding creates permanent joints by fusing two elements with extreme heat, then allowing them to cool in a fixed position. Various types of joint configurations, such as butt-, corner-, edge-, lap-, and tee-welded joints, are determined by the position of welded elements relative to one another.

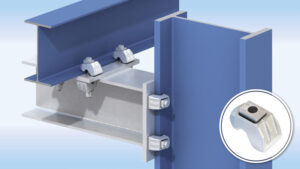

The process of welding creates permanent joints by fusing two elements with extreme heat, then allowing them to cool in a fixed position. Various types of joint configurations, such as butt-, corner-, edge-, lap-, and tee-welded joints, are determined by the position of welded elements relative to one another. Fasteners can be used to create temporary or permanent joints. The ability to create temporary joints allows fasteners to be adjusted, removed, replaced, and/or repaired at any point in the future, without damage to the underlying fastened components.

Fasteners can be used to create temporary or permanent joints. The ability to create temporary joints allows fasteners to be adjusted, removed, replaced, and/or repaired at any point in the future, without damage to the underlying fastened components.

For a video on ICC Approved Steel to Steel Connections, visit

For a video on ICC Approved Steel to Steel Connections, visit  Materials

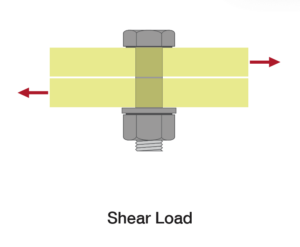

Materials In a shear joint, load forces are at a right angle to the fastener’s axis. In “bearing type” shear joints, joint strength is strictly determined by the shear strength of the fasteners. In these cases, precise fastener tension is less critical, as long as it maintains the fastener in the assembly. Other shear joints use initial clamp load to resist slip and are sometimes referred to as a friction-type or slip-critical joints. These types of joints are commonly found in the construction industry.

In a shear joint, load forces are at a right angle to the fastener’s axis. In “bearing type” shear joints, joint strength is strictly determined by the shear strength of the fasteners. In these cases, precise fastener tension is less critical, as long as it maintains the fastener in the assembly. Other shear joints use initial clamp load to resist slip and are sometimes referred to as a friction-type or slip-critical joints. These types of joints are commonly found in the construction industry. Labor Consideration

Labor Consideration Environmental Factors

Environmental Factors