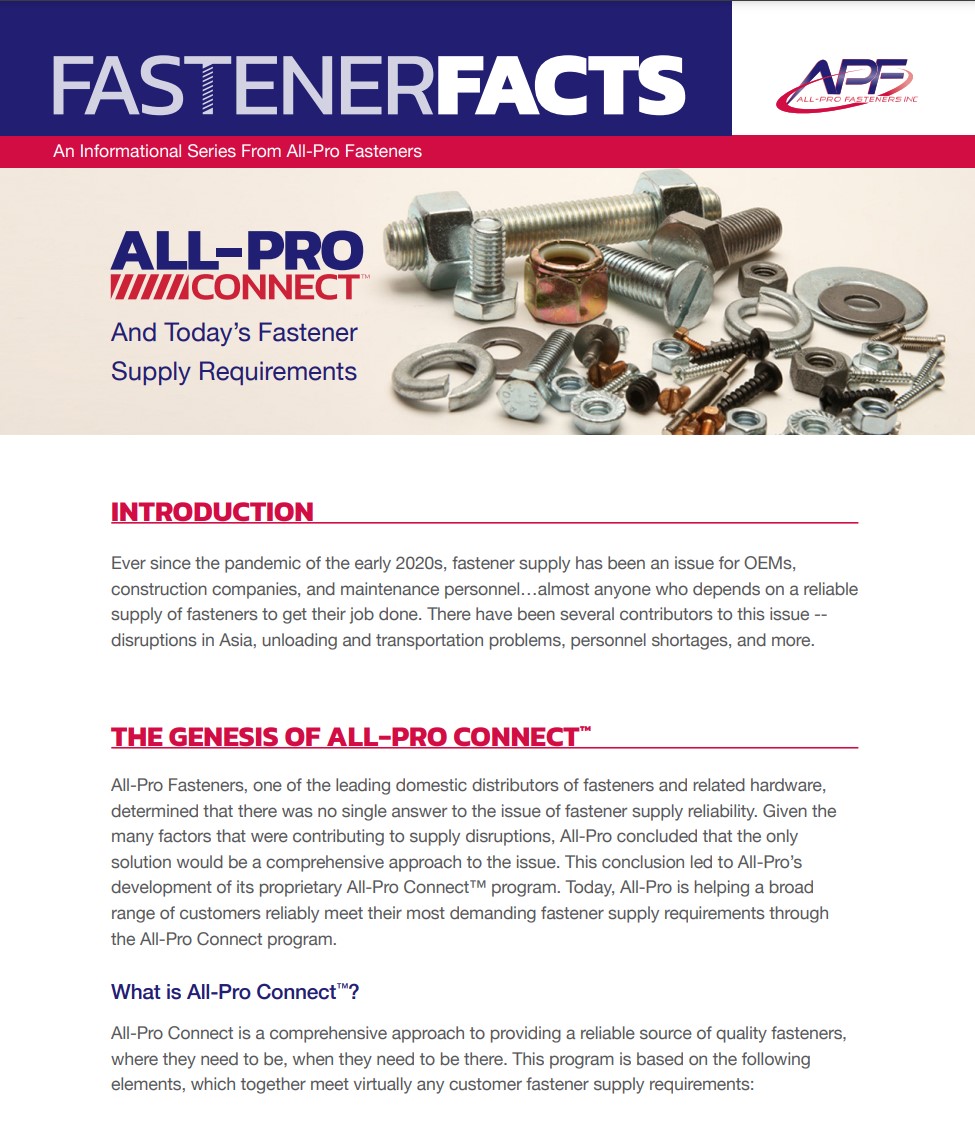

In this paper, All-Pro’s comprehensive approach to fastener supply, All-Pro Connect™, is covered in detail. The paper discusses the core elements of the All-Pro Connect program – global sourcing, domestic manufacturing, VMI/JMI programs, QA/QC processes, and customized shipping – and how they can streamline and optimize a company’s fastener supply effort.

Manufacturing. Sourcing. Services. Solutions.™

Fastener Facts™

Let All-Pro find solutions for you

Talk to our industry specialists about finding the right solution for your application.

Learn MoreAll-Pro Fasteners is continually developing information that is useful to our customers and others involved in fastener selection. Fastener Facts™ is an informational series that explores topics related to the specification, use, and purchase of fastener products.

Managing Fastener Supply for Zero Disruptions

In this paper, we will discuss why fasteners play such an important role in the manufacturing and

assembly enterprise – and how companies can avoid a domino-effect disaster by better managing

their fastener supply.

Building a Better Fastener Supply Chain

At the highest level, a supply chain is designed to support, protect, and enhance the long-term strategic interests of a company. This paper will discuss goals in building a fastener supply chain, identify potential risks, and offer actionable solutions to create a sustainable supply chain that delivers reliable performance as well as continuous improvement.

Fastening vs. Welding: Fabricating Better Joints

Welding is a proven, and sometimes preferred, method of fabricating steel-to-steel connections, but in many applications, fasteners offer advantages in time, cost, and labor savings. This whitepaper discusses a variety of project factors — including materials, surface coatings, load, shear, and bending joints, inspection requirements, labor requirements, safety, logistics, environmental factors, and more.

Fasteners & Corrosion: Avoiding Problems in Advance

Each year, the effect of corrosion on public and private assets represents an equivalent cost of 3.4% of global GDP, according to some estimates. Here we discuss important considerations involved in the selection of fastener materials, designs, and coatings, in order to help design engineers, project managers, and purchasing personnel avoid potential problems that can result from fastener corrosion.

Single Sourcing

Any decision to enter into a single-source relationship is of significant strategic importance to both the buying organization and the supplier. This whitepaper explains how single sourcing provides the potential to negotiate lower costs and better purchasing terms.